TI-PP by MCU at the EMO – Integration of Process Monitoring Toolinspect 2 without PLC changes in existing CNCs

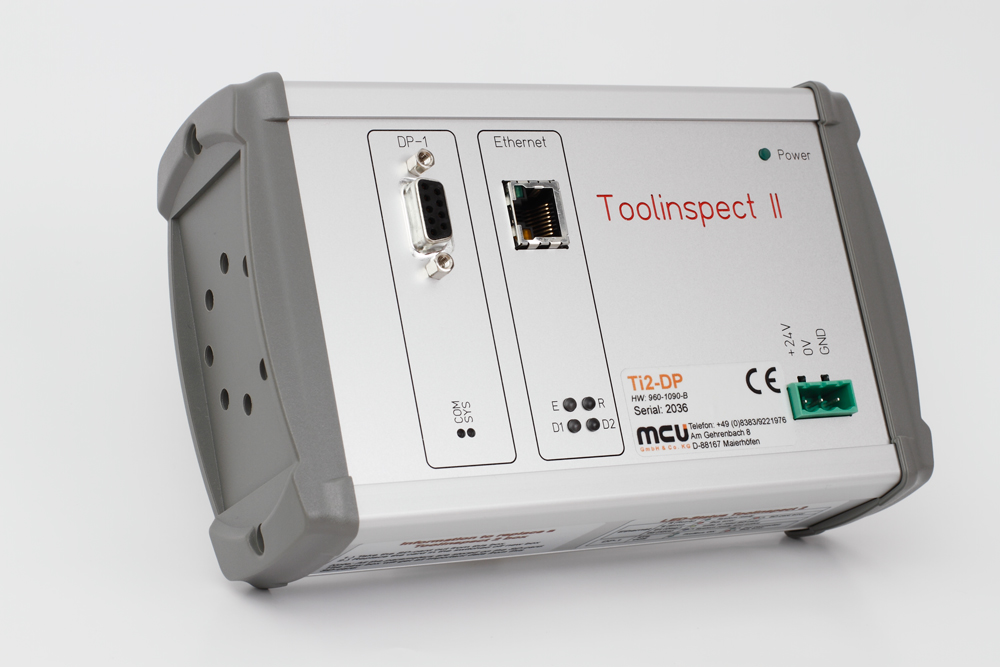

MCU, the pioneering manufacturer of technical process-monitoring systems, will be presenting at this year's EMO (hall 9, booth F32) the TI-PP; a system that can facilitate upgrading Toolinspect 2.

Toolinspect is a system for monitoring cutting processes in general, and that includes machining technologies such as lathe machining, milling, drilling, thread machining or broaching, in which multi-channel turning machines including all the turrets or the numerous axes of machining centers are supported, as are automatic production lines. "Upgrading or retrofitting the leading CNCs of Fanuc or Siemens is quite straightforward, especially due to the fact that changes in the PLC are not necessary. In addition to that, there is no difference in the way you operate the systems", emphasizes Robert Elgaß, head of Sales and Marketing at MCU. "Another advantage is that the NC programming is quite similar to those of OEM systems. Configuration and startup procedure can also be implemented quite easily in existing machinery and machine parks."

The intensifying progress of automation is accompanied by an increase in process types and product diversity, which leads to a significant surge in complexity with regard to the needed range of competencies for operators of machines and facilities. That is the reason why self-optimizing and self-adapting process-monitoring systems that actively support users of machine tools in their tasks are becoming more and more indispensable: systems such as Toolinspect which was launched by MCU for monitoring of machine tools and processes already in the mid-2000s.

Toolinspect 2 enables users to have the system integrated into the operating systems of Windows and Linux. That way, users can flexibly operate the system with the same user interface and an identical interface to the machine and the control system. Process monitoring has been further developed technologically as well: in addition to the standard tool-breakage monitoring, there is now an analysis program that has been made available as an option, as well as a tool-specific and cut-specific wear. The analysis program enables you to view components and machinings in detail, and to calculate essential operating times and non-productive times. "In contrast, the tool-specific and cut-specific wear means that Toolinspect 2 logs the process forces currently running in the machine, and internally stores all the tools that are included. An alarm triggers if the actual value reaches the tool-wear value", explains Robert Elgaß. "Toolinspect 2 analyzes in this way the difference between the tool that is worn out and the new tool. These functionalities and evaluation capabilities can be accessed quite fast, because the system is a real-time system. With TI-PP, we provide users with a system that enables them to put to use the possibilities offered by Toolinspect 2 effortlessly and fast."